In the bustling environment of a commercial kitchen, efficiency and hygiene are paramount. The hood type dishwasher, a staple in commercial kitchens, operates on a principle that balances high efficiency with exceptional cleaning power. To comprehend its functionality, it's essential to break down the key components and steps involved in its operation.

Basic Key Components and Their Roles

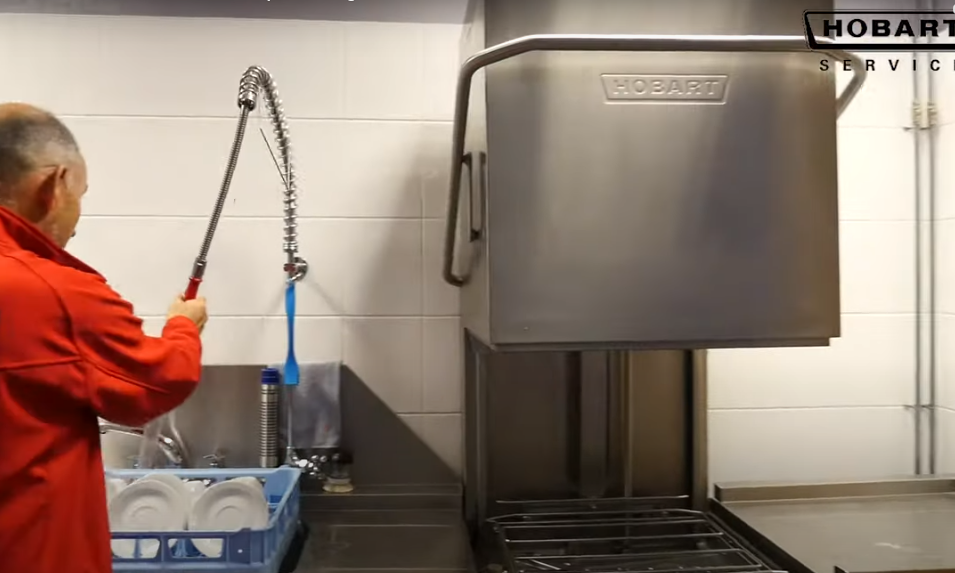

- The Hood: The defining feature of this dishwasher is its hood, which lifts to allow loading and unloading of racks. When lowered, it seals the wash chamber, ensuring optimal washing conditions.

- Wash and Rinse Arms: Located inside the machine, these arms spray water and detergent solution onto the dishes. Wash and rinse arms and nozzles are designed to give even distribution of water around the washing chamber to guarantee that every area is cleaned effectively.

- Control Panel: This allows operators to select different wash cycles and settings depending on the load's requirements.

- Heating Elements: These are used to heat the water to the required temperature for both washing and rinsing, ensuring effective cleaning and sanitisation.

Configurations of drain pumps, break tanks and water softeners are also available depending on the model and brand.

The Washing Process

- Loading: The process begins with loading dirty dishes onto a rack. This rack is then slid into the machine under the open hood.

- Starting the Cycle: Lowering the hood triggers the start of the wash cycle. In automatic models, this action alone can activate the machine, enhancing efficiency without further user input or the need for start button activation. This initiation mechanism, as seen on DC hood type dishwashers, enhances kitchen efficiency, reducing manual intervention and streamlining the dishwashing process.

- The Wash Cycle: Once the cycle starts, hot water mixed with detergent is sprayed onto the dishes through the wash arms. The combination of the detergent and high temperature effectively breaks down food residue and grease.

- Rinsing: Following the wash cycle, the machine switches to rinsing. During this phase, fresh water heated to a high temperature (recommended being at least 82°C), is sprayed to remove any remaining detergent and debris. This step is crucial for hygiene, sanitisation of dishes, preventing spots on the dishes and delivering the ultimate clean.

- Drying: After rinsing, the hood remains closed for a short period to allow the dishes to start drying in the residual heat and steam. Some models may include specific drying cycles.

Advanced Features for Optimal Performance

Hood type dishwashers often boast a range of advanced features. Look out for thermal locks for high temperature rinsing that ensures dishes are rinsed at a consistently high temperature, essential for sanitisation and hygiene. Reduced water consumption is also a key eco-friendly and cost-effective feature in many modern hood type dishwashers, to minimise water usage. Soft start functions, as seen on the Meiko Upster H500 Pass Through Dishwasher, are a highly desirable feature to protect fragile items. This feature gradually ramps up the washing intensity, preventing damage to delicate glassware or china.

Additional Functionalities for Expert Cleaning

Beyond these core features, hood type dishwashers may include:

- Double-Skinned vs Single-Skinned Construction: Double-skinned models offer better insulation, reducing noise and heat loss, while single-skinned versions are more economical and lighter.

- Counterbalanced Hoods: To prevent scalding or burns, some dishwashers feature a counterbalanced hood, which allows hot steam to be released after washing and rinsing cycles without fully opening the hood.

- Heat Recovery Operating Features: Certain models are equipped with heat recovery systems, which reuse heat from steam to pre-heat incoming water, enhancing energy efficiency.

- Exhaust Heat Recovery: This feature, as seen on Winterhalter EnergyPlus pass through dishwasher models, captures and reuses heat from the exhaust, further contributing to energy savings and reducing the kitchen’s overall carbon footprint.

Hood Type Dishwasher Positioning

Hood type dishwashers offer remarkable versatility in their placement within commercial kitchens. Thanks to their adaptable design passthrough dishwashers can optimise workflow. They can be seamlessly integrated into two primary configurations: a straight run or a corner setup, each with its unique advantages and considerations.

In a straight run configuration, the dishwasher is positioned in line with other kitchen equipment. This linear arrangement is particularly efficient in kitchens with ample space and a straightforward workflow. Here’s how it works:

- Entry and Exit Tabling: On either side of the dishwasher, tables are placed for easy loading and unloading. Dirty dishes are stacked on the entry table, then slid into the dishwasher. Once washed, they are removed from the exit side.

- Efficient Workflow: This setup allows staff to operate in a straight line, moving dishes from one end to the other seamlessly, which can be a major time-saver during busy periods.

Alternatively, a corner configuration is an excellent solution for kitchens with limited space or those requiring a more compact workflow.

- Utilising Corner Space: The dishwasher is placed in a corner, often with entry and exit points at right angles to each other. This design makes efficient use of corner space, which might otherwise be underutilised.

- Entry and Exit Tabling: Similar to the straight run, tables are positioned adjacent to the entry and exit points. However, in this setup, they are arranged to accommodate the angular placement, ensuring a smooth workflow around the corner.

The hood type dishwasher's design and operational features make it an invaluable asset in commercial kitchens, where speed, efficiency, and hygiene are non-negotiable. By understanding its functionality, kitchen staff can harness its full potential, ensuring a smooth and effective dishwashing process. The hood type dishwasher is not just a cleaning appliance; it’s a cornerstone of kitchen efficiency and hygiene.