Key Takeaways:

- Effective FOG management in food service operations is essential to prevent potential consequences such as sewer blockages and environmental pollution.

- A grease trap is a device designed to separate and capture grease, oils, and fats from wastewater, preventing them from entering the sewer system.

- There are various types of grease traps including passive manual, automatic, and gravity traps. Each with its own pros and cons.

- Maintaining and cleaning traps regularly is crucial to ensure their proper functioning and prevent blockages.

- Proper FOG management is not only important for compliance with legal requirements but also for protecting the environment and future-proofing businesses against stricter regulations.

- Investing in the correct type and size of grease management solution for individual business requirements and in different water authority areas is critical to staying inline with regulations and safeguarding businesses and the environment.

Effective FOG (fats, oils, and grease) management and implementation is essential for food service business operations. Improper management leads to clogged pipes, sewer backups, costly repairs, and fines. Our guide covers grease trap basics, functionality, and available solutions, with some key takeaways for easy reading.

The History of Grease Traps in the UK

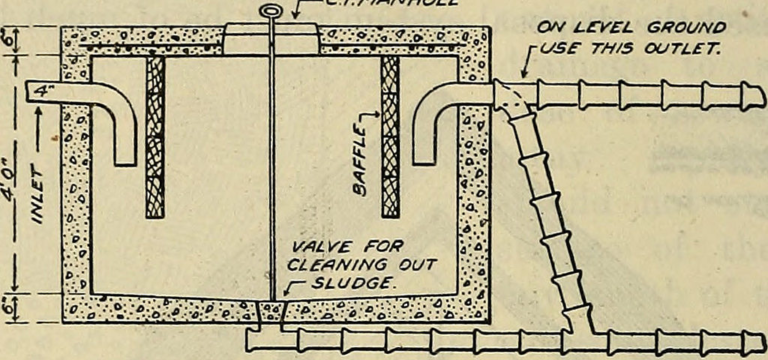

Grease traps, designed to prevent FOGs from entering sewer systems, have a long history. Patented by Nathanial Whiting, the first rudimentary grease trap in the late 19th century. Their use dates back to the Victorian era, coinciding with the development of sewer systems. Modern grease traps, while similar in principle, have evolved in materials and design. The increasing use of commercial kitchens and changing diets have led to greater FOG concerns and stricter regulations.

What is a Grease Trap?

Grease traps prevent FOG from entering the sewer system, where it can cool, solidify, and cause blockages. They intercept and separate FOG from wastewater, allowing cleaner water to flow through. Regular maintenance is essential.

Typically having a box design, a grease trap, depending on the type, will have multiple inner compartments and mechanisms to filter out contaminants. The basic equipment functions by intercepting and separating FOG from wastewater, allowing cleaner water to flow through drainage pipes. This ensures that the sewer system remains free of clogs and reduces the risk of costly repairs to pipework, inconvenience for the surrounding community and environment or fines due to non-compliance with regulations. Regular maintenance and cleaning are essential to keep fat traps operating efficiently.

Food service businesses are the primary contributors to FOG-related blockages, which, combined with solid waste like wet wipes, create significant plumbing problems.

Common terms used to refer to grease traps

- Fat traps: This term emphasises the primary function of grease traps, which is to trap and contain fats.

- Grease interceptors: This name highlights the role of these devices in intercepting and capturing grease before it can cause problems in the plumbing system.

- Grease separators: This term reflects the separation process that occurs within traps, where solid waste settles at the bottom while FOG floats to the top.

- Grease removal units or grease recovery units (GRU's): Used as an alternative term for automatic grease traps. Automatic grease removal units (AGRU's) may also be referenced.

- Oil-water separators: In some cases, particularly in industrial settings, grease traps may be referred to as oil-water separators due to their ability to separate oil and water effectively

It is worth noting that these terms may be used interchangeably depending on regional preferences or industry-specific terminology. However, they all refer to the same device that helps manage FOG in food service and catering operations.

Different Types of Grease Traps

Passive/Manual Grease Traps

Cost-effective, simple installation, but requires frequent manual maintenance and may have odour issues. Effectiveness ranges from 50% to 90% FOG removal.

- Passive hydro mechanical grease traps are designed with a simple yet efficient mechanism that allows for the separation of grease from wastewater.

- These types of grease interceptors typically consist of baffles or plates that slow down the flow of wastewater, allowing gravity to aid in the separation process.

- The captured grease is then trapped within the device, preventing it from entering the sewer system and causing blockages.

| Benefits | Disadvantages |

| Relatively low cost to install and maintain | Require regular cleaning in order to prevent FOG from building up and overflowing into the sewerage system |

| Don’t require any external power source to operate | Can be difficult to clean if they are not installed in an easily accessible location |

| Have a smaller footprint so can be easily installed in most commercial kitchens | Can be susceptible to freezing in cold weather conditions |

Passive or manual traps offer a cost-effective solution for FOG management, ensuring compliance with environmental regulations without relying on complex machinery or automation. Stainless steel grease traps are strong and durable, perfect for indoor positioning. Epoxy coated steel grease traps are also weatherproof making them ideal not only for indoors but also outdoor or underground placement.

Some reports have suggested that, depending on the size and output of the kitchen, passive hydro mechanical (manual) grease traps can effectively remove between 50% and 90% of fats, oils, and greases from wastewater.

Gravity grease traps are also available however are typically installed outdoors and have a much greater flow rate making them perfect for larger establishments.

Automatic Grease Traps/GRUs

More efficient, less maintenance, larger capacity, real-time monitoring, but higher upfront cost and potential mechanical failures. Consider low-profile models for limited space.

- Enhanced Efficiency - Incorporates sensors to detect and skim FOG from wastewater within the trap. Non-mechanical GRU's using pressure to force FOG into a separate fat collection container.

- Large Capacity - Not only a large tank for overall water volume but also equipped with sizable connected storage tanks, sometimes referred to as baskets, that can accommodate significant quantities of FOG.

- Real-time Monitoring - Levels of FOG are clearly visible to monitor when emptying is required.

- Easy Maintenance and Less Down-Time - Unlike passive manual traps, automatic grease GRUs do not need to be completely opened during cleaning so there is less disruption to the business. This allows for continuous operation without frequent shutting down for emptying and cleaning.

- Compliance - Meets all relevant industry standards and regulations for FOG management in food service establishments. Helps businesses stay in compliance with legal requirements to avoid penalties or fines.

| Benefits | Disadvantages |

| Require less frequent cleaning as FOG is broken down by bacteria | Require a larger initial investment as they are more expensive than passive units |

| Easier to clean as FOG is separated out into a separate tank which can be easily disconnected and disposed of responsibly | Require regular maintenance in order to keep them working effectively |

| More effective at preventing blockages as they remove FOG before it has a chance to solidify | Can be susceptible to breakdown if not maintained properly |

| Less susceptible to freezing in cold weather conditions |

Automatic grease removal or recovery units, commonly refered to automatic grease traps, offer numerous advantages over traditional manual or passive hydromechanical grease interceptors. Their automated operation ensures a consistent level of performance, minimising the risk of human error in FOG management. Additionally, these systems provide real-time data on FOG levels, allowing for better monitoring and control.

Looking for more information on grease management solutions? Check out these sizzling comparisons on How Do I Know If I Should Get A Manual Or Automatic Grease Trap?

Bio-dosing Grease Management Solutions

Additional FOG defence can be used with existing systems but can be expensive.

Bio-dosers are not required yet may be used in conjunction with a standalone trap. Using bacteria rather than chemicals to tackle FOG directly in your drain, these solutions, such as GreasePak, distribute the bacteria into pipes that coat the inside walls and break down fats, oils and grease as they flow through.

Bio-dosing equipment and automatic dosing pumps, can also be used to break down FOG within your existing trap which can reduce cleaning frequency. GreasePak Bio-Enzymatic Fluid Refills, GreaseBeta Liquid Fat Digester and GreaseBeta ECO20 Fluid refills are available to allow for continued use. It is advised that bio-dosers always be used alongside a functioning manual FOG trap when being used directly for waste pipes.

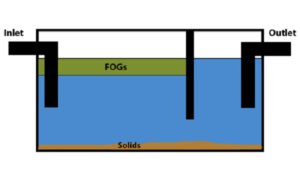

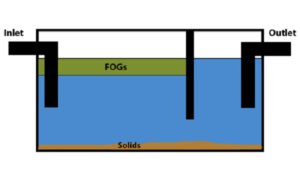

How Does a Grease Trap Work?

Grease traps intercept wastewater from sinks and dishwashers. They operate on the principle that grease is lighter than water and floats while solids settle. Baffles slow the flow, aiding separation. The basic principle allows the grease to rise to the surface or filter out into a separate container while trapping solids and sediment at the bottom, allowing uncontaminated water to continue through to the main system. Depending on the type of trap this separation is achieved through a combination of gravity and buoyancy or via a small heater system.

- Manual/Passive Traps: Use gravity and chambers for separation, slowing down the flow of water so it can cool and separate. FOG is trapped and must be manually removed.

- Automatic Traps/GRUs: Use a heater to prevent cooling and solidifying of FOG. Non-mechanical traps use a form of pressure to force FOG into a separate connected chamber which can then be emptied as required. Mechanical GRUs allow the FOG to cool and solidify in the same way that a passive grease trap does, yet has a skimming mechanism that removes the top layer from waste water periodically into a separate container.

- Bio-dosing: It uses bacteria to break down FOG and can be used with a grease trap.

Read more on How Does a Grease Trap Work?

Which Food Service Premises Need a Grease Trap?

- Commercial kitchens, takeaways and restaurants: These types of premises are one of the major contributors and producers of FOG, and so grease separators are essential to prevent FOG from clogging the sewer system by capturing grease and solids before they enter the drainage system.

- Food service operations: Grease separators are commonly used in food processing plants, catering companies, and other similar establishments to trap FOG and prevent its discharge into the wastewater system.

- Industrial facilities: Industries that generate large quantities of FOG, such as slaughterhouses or oil refineries, utilise fat traps to ensure proper management and disposal of FOG waste.

- Institutional buildings: Hospitals, schools, and government buildings also benefit from grease interceptors to maintain proper wastewater management by removing FOG from the drainage system.

Research carried out by Collin, Thomas et al. in "Towards a risk ranking for improved management of discharges of fats, oils, and greases (FOG) from food outlets" highlights the importance of educating food service businesses and commercial catering settings on the dangers posed by FOG in wastewater, employing effective grease management system and utilising other grease limiting practices.

The Importance of Effective FOG Management in Food Service Operations

As a main user and producer of cooking oil, fats and grease food service businesses contribute a high volume of the FOG that ends up in the mains water system. Appropriate grease management will benefit in many ways.

- FOG management prevents blockages: Proper management ensures that FOG does not clog the sewerage system or drainpipes, preventing costly and time-consuming blockages.

- Environmental protection: Effective FOG management reduces the environmental impact by preventing FOG from contaminating water bodies and affecting aquatic life.

- Compliance with legal requirements: Implementing proper FOG management practices ensures compliance with regulations governing wastewater discharge, avoiding penalties and reputational damage.

- Operational efficiency: By efficiently managing FOG, businesses can avoid disruptions caused by clogged drains or sewers and ensure uninterrupted food service operations.

- Future-proofing against stricter regulations: As regulations surrounding FOG management are expected to become more stringent in the future, implementing effective strategies now can help businesses stay ahead of compliance requirements.

Consequences of Inadequate FOG Management

There are many potential consequences around improper FOG management including blockages and sewage backups which can cause environmental contamination and health risks which could ultimately lead to fines, penalties, and business closure.

Best Practices for Grease Management

Regular maintenance and cleaning, staff education, use of food scrap collectors and sink strainers, and wiping plates before rinsing are just some of the ways that businesses can implement grease management into their practices. Read more about Grease Trap Cleaning & Tips for Grease Management.

Environmental Implications of FOG

As FOG causes blockages this can contribute to harmful bacteria and odours, and can also harm aquatic life and wildlife. Read more about the Effects of Poor Grease Management and FOG on Wildlife & the Environment.

Legal Requirements and Non-Compliance: Choosing the Right Grease Trap

UK Building Regulations (Part H 2.21) require grease separators (EN1825-1, EN 1825-2) or other effective methods in commercial kitchens. Non-compliance leads to fines, reputational damage, and environmental harm.

- Businesses must be aware of the specific legal requirements related to FOG management, particularly in the food service industry. This includes understanding local regulations regarding the installation, maintenance, and inspection of grease traps.

- Failing to comply with legal requirements can have consequences for businesses found to be non compliant or contravening regulations. In addition to potential fines and penalties imposed by regulatory authorities, non-compliant businesses may also face reputational damage. Negative publicity could harm future sales and customer trust.

- Moreover, non-compliance can result in environmental harm as FOG enters the sewerage system. The accumulation of FOG may cause blockages in pipes and wastewater treatment facilities, disrupting the proper functioning of the system.

It is crucial for businesses to stay up-to-date on evolving regulations and take proactive steps towards compliance. By implementing effective FOG management strategies, such as installing and maintaining appropriate grease traps, businesses can mitigate potential risks associated with non-compliance while ensuring a sustainable environment for all.

A real-life case involving inadequate grease management systems and potential contributing behaviours for fatbergs highlights the impact of non-compliance with FOG management regulations. A Nottingham restaurant was found to be repeatedly causing blockages in the area through inadequate grease management and failure to address the situation. A fine was issued for non-compliance, costs to cover remedial works and a victim surcharge. It serves as a stark reminder of the potential consequences that can arise from inadequate FOG management and non-compliance with legal requirements.

Maintenance and Cleaning

Regular inspection, periodic cleaning (by professionals for manual traps), and proper disposal are crucial. Manual traps require kitchen shutdown, while automatic traps are easier to clean. Follow the 25% rule.

Choosing the Right Grease Trap

- Positioning - do you need a unit for indoor, outdoor or underground use? Typically dependent on the size of your business and the number of sinks you wish to run into one trap. It may also dictate the construction materials used for your grease trap. Average sized operations generally opt for indoor situation, typically being housed under the sink, while underground alternatives are better suited to larger premises.

- Kitchen Equipment in Use - Many automatic GRU's are designed with the grease container being removed vertically. This is perfect when used in conjunction with high level equipment with plenty of vertical space between the top of the trap and the equipment it is placed under, if applicable. When grease removal units are used with low-level equipment such as commercial combination ovens or wok cookers, there may not be enough room for vertical removal of the full FOG chamber. As grease traps may be fixed, and therefore unable to be pulled out, an alternative solution is required. Goslyn has a low-profile trap, Goslyn GOSLOC20 Low Level Automatic Grease Trap, that allows the fat collection basket to be removed horizontally rather than vertically, to allow for applications that are limited by space.

- Size and Capacity - the dimensions of the equipment in relation to the intended position e.g. grease traps under sinks, for commercial dishwashers or used in conjunction with specific cooking equipment such as combination ovens and wok cookers.* The more FOG the kitchen produces, the larger the grease trap and greater capacity is needed.

- Water Flow - the volume of wastewater that the kitchen deals with.

- Number of sinks and the volume or the quantity of equipment connected to the waste outlet - In the case of sinks take the number of sinks used on the premises and the volume. Use a quick formula to approximate the volume of each - calculate volume of a single sink by multiplying the height, width and depth. Multiply this value by 0.003 to find the GPM (gallon per minute). If you have multiple sinks, multiply the volume of a single sink by the total number of sinks before multiplying by 0.003. Read more about What Size Grease Trap Do I Need?

- Type - passive/manual grease traps or automatic gru's.

- Maintenance and cleaning - passive and manual traps will require complete cleaning of the whole unit while automatic traps with a separate FOG basket can simply remove and empty the attached container only according to disposal guidelines.

- Additional filtration systems or pre-treatment devices - does the premises require additional bio-dosing equipment.

- Lifetime Cost - Consider the cost of installation and the availability of parts should any replacement be required. The initial outlay is only part of the total outlay. Always consider the cost of repair when required, cleaning, chemicals if needed and responsible disposal of waste materials and FOG. Read more about The True Cost of a Grease Trap

*Did you know that some water authorities are recommending a 400 litre passive system for Chinese takeaways that use a wok cooker? The majority of kitchens would not be able to accommodate this, however an automatic grease trap is a suitable alternative. Don't think that you'll slip under the radar by installing just any sized grease trap - it must meet requirements to satisfy regulations. Why Installing Grease Traps is Essential for Chinese Restaurants & Takeaways

Consult professionals and your local water authority. Different water authorities may have different criteria, Thames Water and Severn Trent seem to be the most diligent and so it is vital that you correspond and work closely with your local authorities to ensure your business meets the requirements for your area.

Grease management FAQs

What is the impact of FOG on the UK sewerage system?

It is reported that approximately half a million tonnes of FOG is deposited into the UK mains drainage system annually. This may be from domestic and commercial premises, although primarily food service and catering premises where a large amount of used cooking oils, fats and oils are created. This grease and FOG when cooled, solidifies and sticks to pipe walls, leading to blockages and eventually fatbergs when combined with solid waste, while fats and oils damage waste water treatment equipment, costing authorities millions in repairs.

Why is legislation being enforced for FOG management by food service operators?

Legislation is being enforced to ensure effective FOG management due to the serious environmental damage caused by fats, oils, and grease if they enter natural water courses. Polluters can face large fines or closure if FOG waste isn't managed properly.

How does a grease trap work?

A grease trap is a receptacle that intercepts and traps fats, oils, and grease (FOG) from wastewater before it enters a drainage system. FOG floats on top of water allowing for separation. Grease rises to the top and is trapped using baffles, while clear water escapes under an outlet baffle. Solids settle at the bottom.

What are the different types of grease traps?

There are three main types of grease traps: passive or manual, automatic, and gravity. Passive traps are manually cleaned, automatic traps re-heat and skim out FOG automatically, and gravity traps are large in-ground tanks. Additional bio-dosing equipment is also available to help break down FOG in grease traps or pipes.

How often should a grease trap be cleaned?

The time between cleaning depends on wastewater production and the grease trap's size. Generally, it is recommended to clean/pump out the trap every 2-4 weeks. Adding a biological grease treatment fluid can extend this period to up to 8 weeks. Pay attention to the 25% rule - the total depth of the sediment and floating fat layer should not exceed 25% of the total liquid depth.

What are the benefits of using an automatic grease trap?

Automatic grease traps, also known as grease removal units (GRU's or AGRU's), automatically re-heat and skim out FOG. This eliminates the need for manual measurements and checks. Although they have a higher initial cost, they are more efficient and have lower long-term running and servicing costs compared to manual grease traps.