Grease traps are essential for preventing FOG (fats, oils, and grease) from clogging sewer systems. Dosing systems enhance grease trap effectiveness.

What is a Biological Dosing System?

Biological dosing systems use bacteria to break down FOG into harmless compounds. A specific strain of non-pathogenic bacteria are introduced into the grease trap. These live bacteria are selected for their ability to digest and consume FOG efficiently.

The system works on a simple principle: it continually doses the grease trap with a biological solution, often in liquid form. The bacteria in the solution feast on the FOG, multiplying and establishing colonies. As they break down the waste, they convert it into water and carbon dioxide, significantly reducing the amount of grease in the trap and the frequency of manual cleaning required.

What is an Enzyme Dosing System?

Enzyme dosing systems use enzymes (lipase, amylase, and protease) to accelerate FOG breakdown. Lipase breaks down fats, amylase targets starches, and protease deals with proteins. Enzymes catalyse the breakdown of FOG molecules into smaller, more water-soluble particles.

While enzyme systems break down FOG into smaller particles, they don't use live organisms and so don't completely consume fats, oils and grease as biological systems do. The smaller particles flow more easily and further through drainage systems however may still cause a problem further down the line, over an extended period of time.

Does Combining Enzymatic and Biological Dosing Systems Work?

Yes, it is possible to combine enzymatic and biological dosing systems, creating a bio-enzymatic approach. This combination harnesses the benefits of both systems: the enzymes quickly break down FOG into smaller particles, which the bacteria can then consume more easily.

Where are Dosing Systems Installed?

These dosing systems are typically installed directly into the passive (manual) epoxy steel grease traps or stainless steel grease trap or into the drainage system that feeds into the trap. Placement is crucial for maximising contact time between the enzymes/bacteria and the FOG.

The dosing units are often set up to release the biological or enzymatic solution at regular intervals, usually during the establishment's off-hours, to maximise efficiency and reduce interference with kitchen operations.

Grease Digesting Bio-Dosers: A Standalone Solution?

Bio-dosing is a popular solution for the fatberg problem. But can it replace grease traps?

Grease Traps vs. Bio-Dosers

Grease traps intercept wastewater, slowing it down to allow FOG to cool, solidify, and float to the top while solids settle. Bio-dosers use bacteria or enzymes to break down FOG, either in the drains or within the grease trap rather than trap it.

Can Bio-Dosers Replace Grease Traps?

To answer this, it’s best to begin by specifying that there are two types of bio-dosers: those which work in your drains, and those which work in your grease traps.

Bio-dosers working in drains are sometimes proposed as grease trap replacements.

For Drain/Waste Pipe Dosing

GreasePak System

The GreasePak Biological Drain Maintenance System doses your waste water pipe every night with a multi-strain bacterial formula which is capable of breaking down even the most stubborn long-chain fatty acids, oils and greases. With these regular doses, it maintains a bio-film coating on the walls of your drains which begins to digest FOGs as soon as they slip past.

Small and compact, the GreasePak slots neatly into place on the wall by your waste water pipe. The wall-mounted bio-enzymatic dosing system contains a control and a replaceable cartridge of bacterial solution. The system doses the trap at set intervals, ensuring a constant supply of active bacteria.

The solution is non-toxic and safe for food preparation areas. Refill packs and accessories (mounting brackets, battery packs, alarm systems) are available.

GreasePak Cost:

- Mains-powered unit: Just over £588 (incl. VAT)

- Battery-powered unit: Just under £518 (incl. VAT)

- Battery replacement (every two years): £56

- 3-month refill: Just over £163

GreasePak prevents drain blockages and associated odours. However, due to the wastewater flow rate, it won't eliminate all FOG waste. Thus, it is not a complete solution to the fatberg problem.

For Grease Trap Dosing

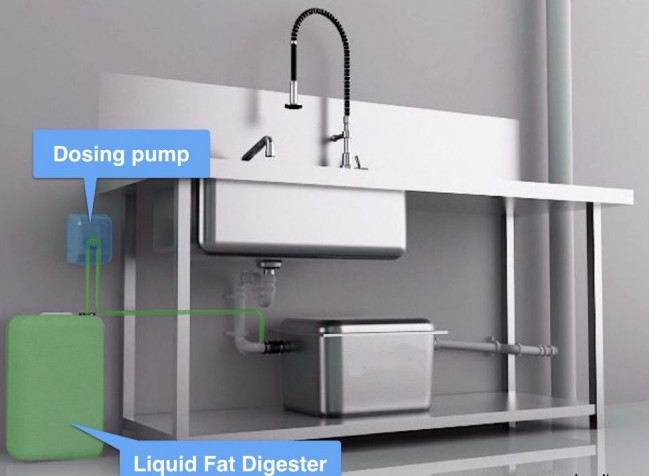

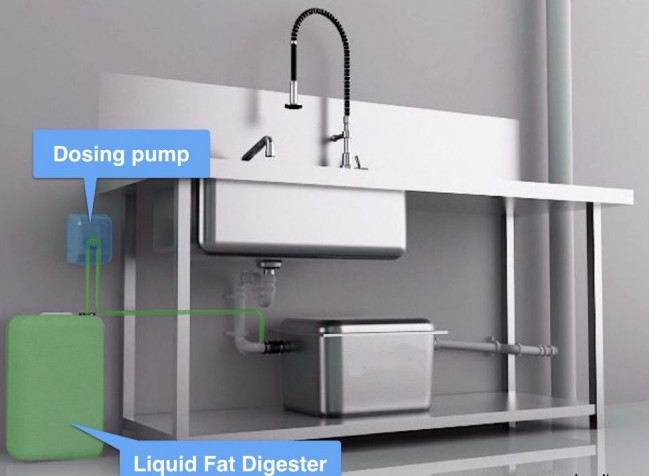

BDP Dosing Pump

This is a more affordable option that requires an automatic battery powered dosing pump and a liquid fat digester. The pump releases doses into the grease trap, breaking down FOG and slowing fill-up.

Dosing Pump Cost:

- Pump: £190 (incl. VAT)

- 3-month supply of digester: Just under £120

*All prices are correct at the time of posting.

Build on Grease Trap Basics with Bio-Dosing

Grease traps are the primary and most basic form of grease management and FOG prevention however bio-dosers enhance grease trap function by slowing FOG accumulation. This is good for two reasons:

- Grease traps become less efficient once they are over 25% full, and so bio-dosers will ensure that your grease trap stays working efficiently for much longer.

- If you dread cleaning out your grease trap every few weeks, a bio-doser helping to break down the FOGs in your drains or in your trap can make clean-up operations less frequent.

Basically: Bio-dosing keeps your trap working well while saving you labour.

Grease traps remain the primary solution for FOG management. Bio-dosing can be a valuable addition, improving grease trap performance and reducing maintenance.